Quality Standards for filling machines. Part 3 of our blog series: Materials

In the third part of our blog series, we focus on the essential aspects relating to the materials used. The materials used in the manufacture of a filling machine have a significant influence on its performance and durability, as well as on ensuring product safety, hygiene and compliance with legal regulations.

A high-quality food filling machine is characterised by the fact that it is made of materials that fulfil the criteria presented below.

1. Product Safety and Corrosion Resistance

The materials that make up a filling machine can come into direct contact with the products to be filled. It is therefore important to select materials that can neither release harmful substances nor contaminate the product. This is particularly true in the food and pharmaceutical sectors, where the materials must be food-safe and harmless.

Furthermore, filling machines often come into contact with liquids or chemicals. It is therefore important to choose materials that are resistant to corrosion in order to extend the service life of the machine and reduce the frequency of repairs or replacements.

2. Hygiene Requirements

Strict hygiene regulations play a crucial role in various sectors, especially in the food industry. It is very important that the materials used are easy to clean in order to prevent the accumulation of dirt, microorganisms and bacteria. A smooth and non-porous surface design makes cleaning processes much easier.

It is also essential to strictly avoid any right angles in areas that come into contact with the product and to use curves wherever possible. Indentations or gaps, in which the product does not flow but adheres permanently, are also not permitted.

3. Resistance to Wear and Tear and Durability

Daily use and mechanical stress are inevitable for filling machines. High-quality materials contribute to the robustness and durability of the machine, ensuring its performance over time.

4. Resistance to Temperatures and Chemicals

Depending on the type of products being filled, machines may come into contact with different temperatures and chemicals. The materials used must be able to withstand these conditions without compromising their structure or properties.

5. Compatibility with Cleaning Agents

Cleaning agents such as alkaline solutions or acidic disinfectants are often used when cleaning the filling machine. In this context, it is crucial that the materials used, such as stainless steel or food-safe plastics, are resistant to such chemicals to prevent possible damage and ensure that cleaning is efficient.

6. Compliance with Standards

Certain industries have specific requirements for the materials used. It is important to ensure that the materials used comply with the relevant industry standards and regulations, such as FDA approval for the food industry.

Our tip: Before purchasing your filling machine, make sure that the manufacturer can guarantee the described material requirements.

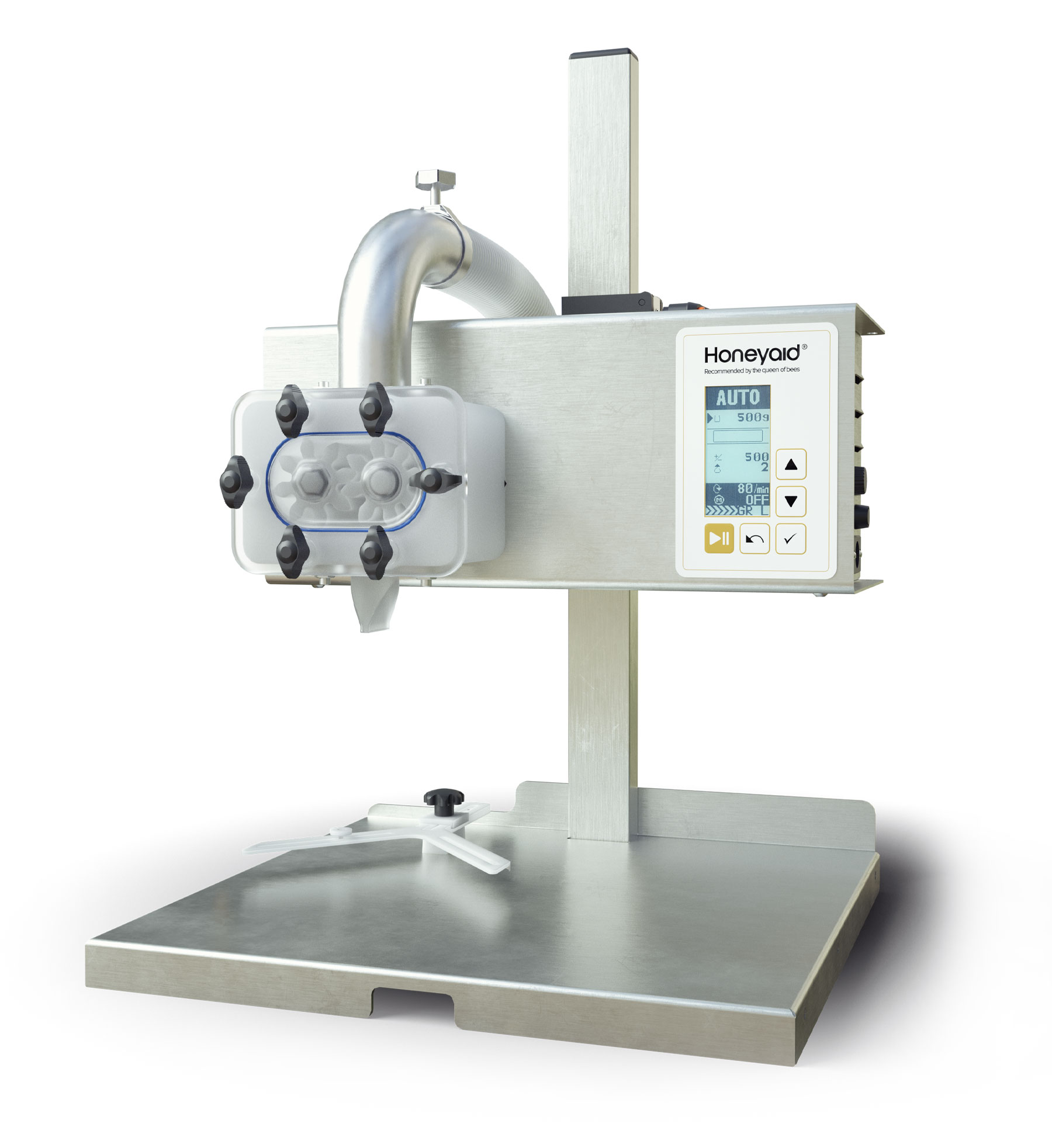

Robust and certified materials of the Honeyaid® honey filling machine

All components of the bottling machine that come into direct contact with food and are used in the filling of food are certified for use with food. These components are characterised by smooth surfaces, making them extremely easy to clean and disinfect. We will be happy to provide you with the relevant certificates.

Robust and certified materials such as AISI 316L stainless steel, POM and silicone are used for the stand, the gear pump head and the hoses, ensuring a long service life.

Our tip: Did you know that AISI 316L stainless steel can even be easily cleaned in industrial dishwashers without rust film forming?

Materials used in the "Made in China" honey filling machine

The pipe bend made of die-cast stainless steel protrudes into the pump head. Such constructions lead to undesirable deepenings or gaps, which are not acceptable in the food sector. In addition, cleaning requires the pipe bends to be dismantled. However, this is problematic as they are firmly connected to the pump head with Teflon tape, which means that such cleaning is not intended or is difficult to realise. (Fig. 1 and 2) The same applies to the filling holder with the right-angled filling pipe. (Fig. 3)

All parts of our blog series Quality Standards for filling machines or What do I have to consider when buying a honey filling machine?

- Part 1: General rules and regulations

- Part 2: Construction

- Part 3: Materials

- Part 4: Durability

Share this post:

Related Posts

18.04.2024

HONEYAID®’s ‘Busy as a Bee’ T-Shirt

Our new "Busy as a Bee" collection by HONEYAID® is a must-have for beekeepers and nature enthusiasts seeking something special.

09.04.2024

Looking to fill more than just honey?

From jams to fruit juices to spreads, our FILLOGY® Neo offers a wide range of applications.

28.02.2024

What do I have to consider when buying a honey filling machine? Part 4: Durability

By investing in a machine that is robust over the long term, you ensure continuous and efficient production for your business.

09.11.2023

International Conference of the Arab Beekeepers Union

Visit us at the exhibition of the 14th International Conference of the Arab Beekeepers Union

08.08.2023

What do I have to consider when buying a honey filling machine? Part 2: Construction

After taking a closer look at the rules and regulations that apply to honey filling machines in the first part of our blog series, we now want to look at the resulting design aspects based on the core piece of a filling machine, the pump head.

20.06.2023

What do I have to consider when buying a honey filling machine? Part 1: General rules and regulations

Part one of our blog series: Applicable standards and directives for machinery in the food sector

24.05.2023

Pumping over for cream stirring with Honeyaid®

With the Honeyaid® bottling machine you fill honey in seconds, but in addition you can also use it to pump and cream honey.

13.04.2023

The Nassenheider® Fill Up 2 becomes Honeyaid®

For over 20 years, beekeepers have valued the original Nassenheider® Fill Up 2 for efficient and reliable dosing of honey. From now on, the semiautomatic honey filling machine …

14.02.2023

From Dresden, all over the world

We have been delivering Honeyaid® filling machines from our small boutique manufacturing company in Dresden to (almost) all countries worldwide.

13.02.2023

Three tips for cleaning

Thanks to its highly compact design, the Honeyaid® is easy and quick to clean. We tell you how to clean your machine optimally so it is in perfect condition for subsequent use.

12.02.2023

Honey bottling at MyHONEY

The MyHONEY project aims to give life to at least 200 new bee colonies every year. To this end, it offers bee sponsorships for companies.

10.02.2023

Women for Bees

Women for Bees is a state-of-the-art female beekeeping entrepreneurship programme launched by UNESCO and Guerlain.

09.02.2023

Bee pollination programs for farmers

The biotech company Beeflow creates and manages pollination programs for farmers which increase crop yields by up to 60%.