Quality Standards for filling machines or What do I have to consider when buying a honey filling machine?

A short while ago, we received a call from a beekeeper who found himself in a dire situation. The reason? The Veterinary and Food Control Office had informed him of the imminent closure of his business. The beekeeper had recently purchased a low-cost honey filling machine from the Far East. Unfortunately, this machine did not meet the necessary regulatory standards, including those pertaining to food safety. As a result, he failed to obtain the required operating license for the Chinese-made filling machine. Regrettably, he was unaware of the applicable rules and regulations governing filling machines.

Based on our experience, we know that he is not the only one in that. Consequently, we would like to provide you with some valuable advice to consider when purchasing your honey filling machine. We start our little blog series with the generally applicable rules and discuss the topics of construction, materials and durability in the next episodes.

Part 1 of our blog series: Applicable standards and directives for machinery in the food sector

Directives and standards at both the EU and national levels outline the specifications and materials that must be employed in food processing machinery.

EU regulations:

The Machinery Directive (2006/42 EC) is the most important directive concerning the design of machinery. Other EU regulations govern the use of materials and articles that come into contact with food. These include, for example, Regulation (EU) No. 10/2011 and (EC) No. 1935/2004.

EU directives and regulations establish specific safety standards and health requirements for various products, including machinery and electrical appliances. By obtaining CE marking, manufacturers demonstrate their knowledge and compliance with the relevant product requirements and regulations. It is important to note that products lacking the CE marking are prohibited from being sold within the European Union.

Our tip: Ask your distributor or the manufacturer about the CE marking before buying the machine. A CE-marking must be indicated on the type plate of a machine.

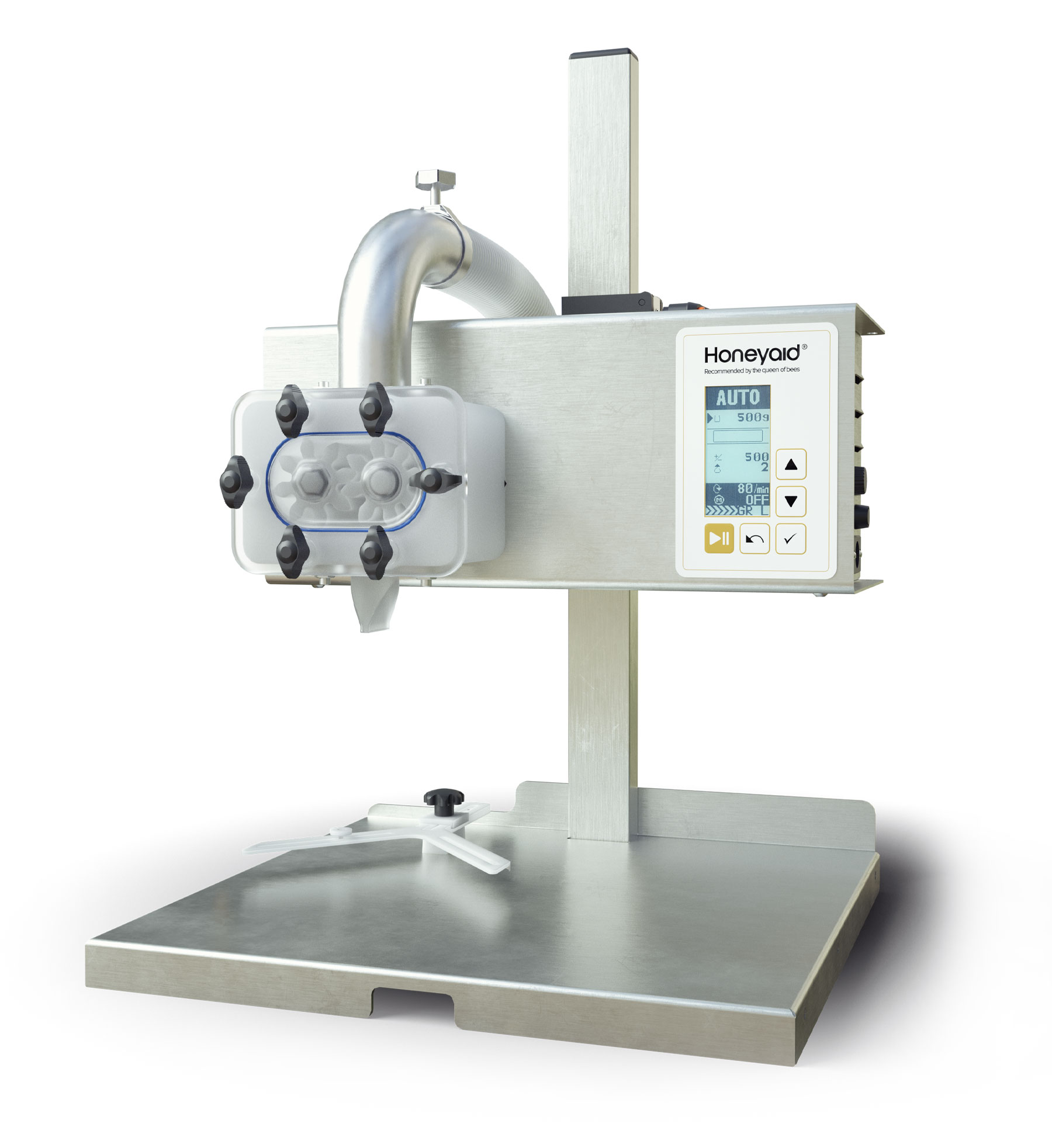

At Filling Evolution GmbH in Dresden, our Honeyaid® filling machine, along with all our other machines, is meticulously designed and manufactured by our expert team. Throughout the development and production process, we consistently ensure compliance with the relevant regulations. As a result, we confidently declare that our filling machines conform to the EC Machinery Directive (2006/42/EC, Annex II A) and other applicable EU regulations. The CE mark, affirming compliance, can be found on the type plate of our machines. Moreover, our company undergoes regular inspections by the local food inspection office, which includes on-site visits to ensure compliance and quality control.

National regulations in Germany:

At the national level, reference should also be made to the Food Hygiene Ordinance – LMHV, i.e. the Ordinance on Hygiene Requirements for the Production, Handling and Placing on the Market of Food.

The LMHV encompasses various provisions, including guidelines pertaining to process hygiene, specifically addressing hygiene standards during food processing. All individuals involved in the production and distribution of food, including beekeepers who sell honey, are obliged to adhere to the regulations stipulated in the Food Hygiene Ordinance.

The LMHV generally requires that a food must not be exposed to any negative influence at all stages of production and processing. Standards tailored specifically to beekeeping can be found in the guideline Standard QM Honig und Imkerei®.

The chapter on honey processing specifies that all surface in contact with honey must be easy to clean. They must be made of stainless steel, food-grade plastics or glass. The equipment and installations must be constructed in such a way that cleaning and maintenance work can be carried out effectively.

The Honeyaid® is meticulously designed to ensure that all parts and surfaces are smooth, quick and easy to clean. All machine parts that come into contact with the product are food-grade certifided.

Finally, the calibration law holds significant importance for beekeepers who sell their honey as it requires the use of a calibrated and recalibratable scale. In the case of our customer, the Chinese machine they purchased falsely indicates compliance with this law through its integrated scale. However, it is crucial to note that the built-in scale is neither calibrated nor verifiable, resulting in a violation of German legislation. While our Honeyaid® machines are highly accurate volumetric fillers, we strongly recommend our customers to conduct random checks of the fillings using a calibrated scale.

All parts of our blog series Quality Standards for filling machines or What do I have to consider when buying a honey filling machine?

- Part 1: General rules and regulations

- Part 2: Construction

- Part 3: Materials

- Part 4: Durability

Share this post:

Related Posts

18.04.2024

HONEYAID®’s ‘Busy as a Bee’ T-Shirt

Our new "Busy as a Bee" collection by HONEYAID® is a must-have for beekeepers and nature enthusiasts seeking something special.

09.04.2024

Looking to fill more than just honey?

From jams to fruit juices to spreads, our FILLOGY® Neo offers a wide range of applications.

28.02.2024

What do I have to consider when buying a honey filling machine? Part 4: Durability

By investing in a machine that is robust over the long term, you ensure continuous and efficient production for your business.

09.11.2023

International Conference of the Arab Beekeepers Union

Visit us at the exhibition of the 14th International Conference of the Arab Beekeepers Union

08.11.2023

What do I have to consider when buying a honey filling machine? Part 3: Materials

The materials used in the manufacture of a filling machine have a significant influence on its performance and durability, as well as on ensuring product safety, hygiene and compliance with legal regulations.

08.08.2023

What do I have to consider when buying a honey filling machine? Part 2: Construction

After taking a closer look at the rules and regulations that apply to honey filling machines in the first part of our blog series, we now want to look at the resulting design aspects based on the core piece of a filling machine, the pump head.

24.05.2023

Pumping over for cream stirring with Honeyaid®

With the Honeyaid® bottling machine you fill honey in seconds, but in addition you can also use it to pump and cream honey.

13.04.2023

The Nassenheider® Fill Up 2 becomes Honeyaid®

For over 20 years, beekeepers have valued the original Nassenheider® Fill Up 2 for efficient and reliable dosing of honey. From now on, the semiautomatic honey filling machine …

14.02.2023

From Dresden, all over the world

We have been delivering Honeyaid® filling machines from our small boutique manufacturing company in Dresden to (almost) all countries worldwide.

13.02.2023

Three tips for cleaning

Thanks to its highly compact design, the Honeyaid® is easy and quick to clean. We tell you how to clean your machine optimally so it is in perfect condition for subsequent use.

12.02.2023

Honey bottling at MyHONEY

The MyHONEY project aims to give life to at least 200 new bee colonies every year. To this end, it offers bee sponsorships for companies.

10.02.2023

Women for Bees

Women for Bees is a state-of-the-art female beekeeping entrepreneurship programme launched by UNESCO and Guerlain.

09.02.2023

Bee pollination programs for farmers

The biotech company Beeflow creates and manages pollination programs for farmers which increase crop yields by up to 60%.