Quality Standards for filling machines. Part 2 of our blog series: Construction

After taking a closer look at the rules and regulations applying to honey filling machines, we now shall look at the design aspects based on the core piece of a filling machine, the pump head.

This will enable you to make an initial assessment of the quality of the machine on offer before you buy a filling machine.

Generally speaking:

- Surfaces should be designed for effortless cleaning, with no gaps, unreachable areas, fractures, or recesses where product or cleaning remnants could accumulate. This requirement also extends to the junctions between individual components.

- All individual parts to be cleaned should be designed in such a way that cleaning can be carried out effectively.

- Components to be cleaned should be practical and easy to dismantle.

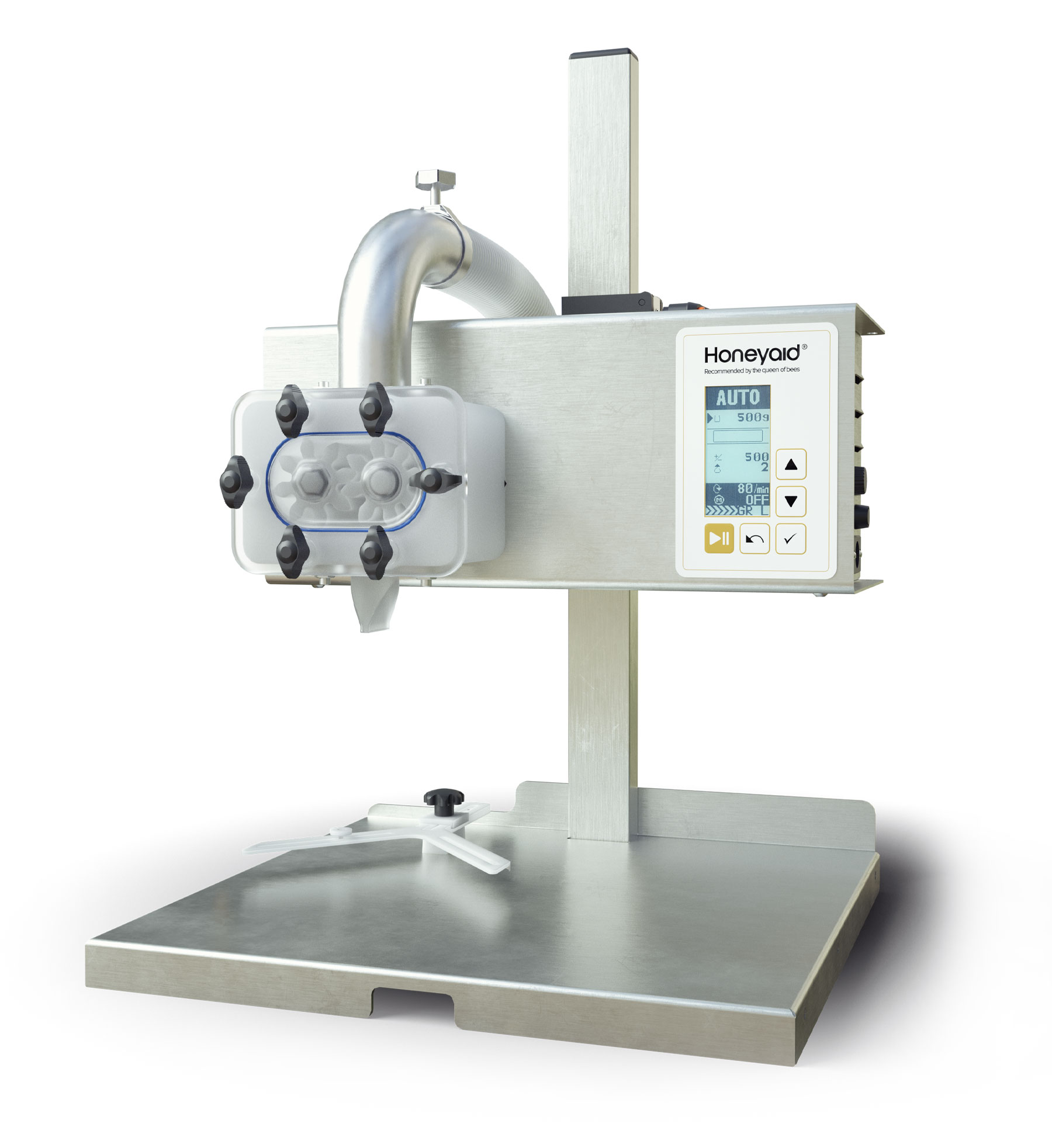

We have solved these requirements for the gear pump head of the Honeyaid® honey filling machine as follows:

- The material has smooth surfaces without indentations or gaps.

- The pump head can be dismantled and disassembled into its individual parts within three minutes, after which all parts are cleaned in the dishwasher.

- It is made of certified food-safe materials: POM, AISI 316L and silicone.

- Seals, screws, lids, gears and drive shaft can be reordered from our online shop at any time in case of wear or defects. We recommend replacing all seals after 20,000 kg or at least once a year.

Our tip: If you would also like to disinfect the parts that come into contact with food, we will be happy to advise you on suitable products.

In contrast, the gear pump head of the honey filling machine sourced from the Far East mentioned in the first part of our blog series presents the subsequent issues.

Gear pump head of the honey filling machine “made in China":

- 1 The pump head is permanently installed and cannot be easily dismantled. The lid cannot be dismantled or can only be dismantled with difficulty due to the seals (light blue) over the screws. Regular and thorough cleaning of the pump head is hardly possible.

- 2 When water is pumped through (to enable some kind of cleaning), water and product residues collect in the pump head. This leads to contamination of the product.

- 3 The pipe bends made of die-cast stainless steel protrude into the pump head at the top and bottom. According to the Machinery Directive for Foodstuffs, these spaces should be explicitly avoided. They are only permitted if they are very easy to clean. Here, however, the inlets and outlets are anchored with Teflon tape for a permanent fit.

- 4 Hexagon head screws are not approved for contact with food because the screw heads cannot be cleaned.

Other components of the Honeyaid® honey filling machine:

The remaining elements of the Honeyaid® honey filling machine also adhere to the necessary legal standards. Both the machine and its stand are constructed using stainless steel. However, there are additional particulars concerning the assembly of the individual components that require careful attention in this aspect as well.

Once more, it is crucial to ensure that the filling machine’s spraying area is devoid of substantial openings (as depicted in the illustrative example below). This precaution is necessary to prevent the accumulation of contaminants in these inaccessible regions over time:

Our tip: Before buying, make sure that the manufacturer complies with the hygiene and cleanability requirements of the machine as stipulated by the European Machinery Directive in the field of food processing machinery.

All parts of our blog series Quality Standards for filling machines or What do I have to consider when buying a honey filling machine?

- Part 1: General rules and regulations

- Part 2: Construction

- Part 3: Materials

- Part 4: Durability

Share this post:

Related Posts

18.04.2024

HONEYAID®’s ‘Busy as a Bee’ T-Shirt

Our new "Busy as a Bee" collection by HONEYAID® is a must-have for beekeepers and nature enthusiasts seeking something special.

09.04.2024

Looking to fill more than just honey?

From jams to fruit juices to spreads, our FILLOGY® Neo offers a wide range of applications.

28.02.2024

What do I have to consider when buying a honey filling machine? Part 4: Durability

By investing in a machine that is robust over the long term, you ensure continuous and efficient production for your business.

09.11.2023

International Conference of the Arab Beekeepers Union

Visit us at the exhibition of the 14th International Conference of the Arab Beekeepers Union

08.11.2023

What do I have to consider when buying a honey filling machine? Part 3: Materials

The materials used in the manufacture of a filling machine have a significant influence on its performance and durability, as well as on ensuring product safety, hygiene and compliance with legal regulations.

20.06.2023

What do I have to consider when buying a honey filling machine? Part 1: General rules and regulations

Part one of our blog series: Applicable standards and directives for machinery in the food sector

24.05.2023

Pumping over for cream stirring with Honeyaid®

With the Honeyaid® bottling machine you fill honey in seconds, but in addition you can also use it to pump and cream honey.

13.04.2023

The Nassenheider® Fill Up 2 becomes Honeyaid®

For over 20 years, beekeepers have valued the original Nassenheider® Fill Up 2 for efficient and reliable dosing of honey. From now on, the semiautomatic honey filling machine …

14.02.2023

From Dresden, all over the world

We have been delivering Honeyaid® filling machines from our small boutique manufacturing company in Dresden to (almost) all countries worldwide.

13.02.2023

Three tips for cleaning

Thanks to its highly compact design, the Honeyaid® is easy and quick to clean. We tell you how to clean your machine optimally so it is in perfect condition for subsequent use.

12.02.2023

Honey bottling at MyHONEY

The MyHONEY project aims to give life to at least 200 new bee colonies every year. To this end, it offers bee sponsorships for companies.

10.02.2023

Women for Bees

Women for Bees is a state-of-the-art female beekeeping entrepreneurship programme launched by UNESCO and Guerlain.

09.02.2023

Bee pollination programs for farmers

The biotech company Beeflow creates and manages pollination programs for farmers which increase crop yields by up to 60%.