Quality Standards for filling machines. Part 4 of our blog series: Durability

In the final section of our series, we focus on the significant aspect of longevity in your filling machine. By investing in a machine that is robust over the long term, you ensure continuous and efficient production for your business. This extends beyond technical features and significantly influences the overall performance and profitability of your production facility.

What are the decisive factors for the longevity of your filling line?

1. High-quality materials

Choosing the right materials is crucial. The use of robust, corrosion-resistant and abrasion-resistant materials ensures that the filling machine can withstand the demands of daily operation in the long term.

2. Solid Construction

A stable design and precise manufacturing are also crucial. A solid base ensures that the filling machine functions stably even under demanding conditions.

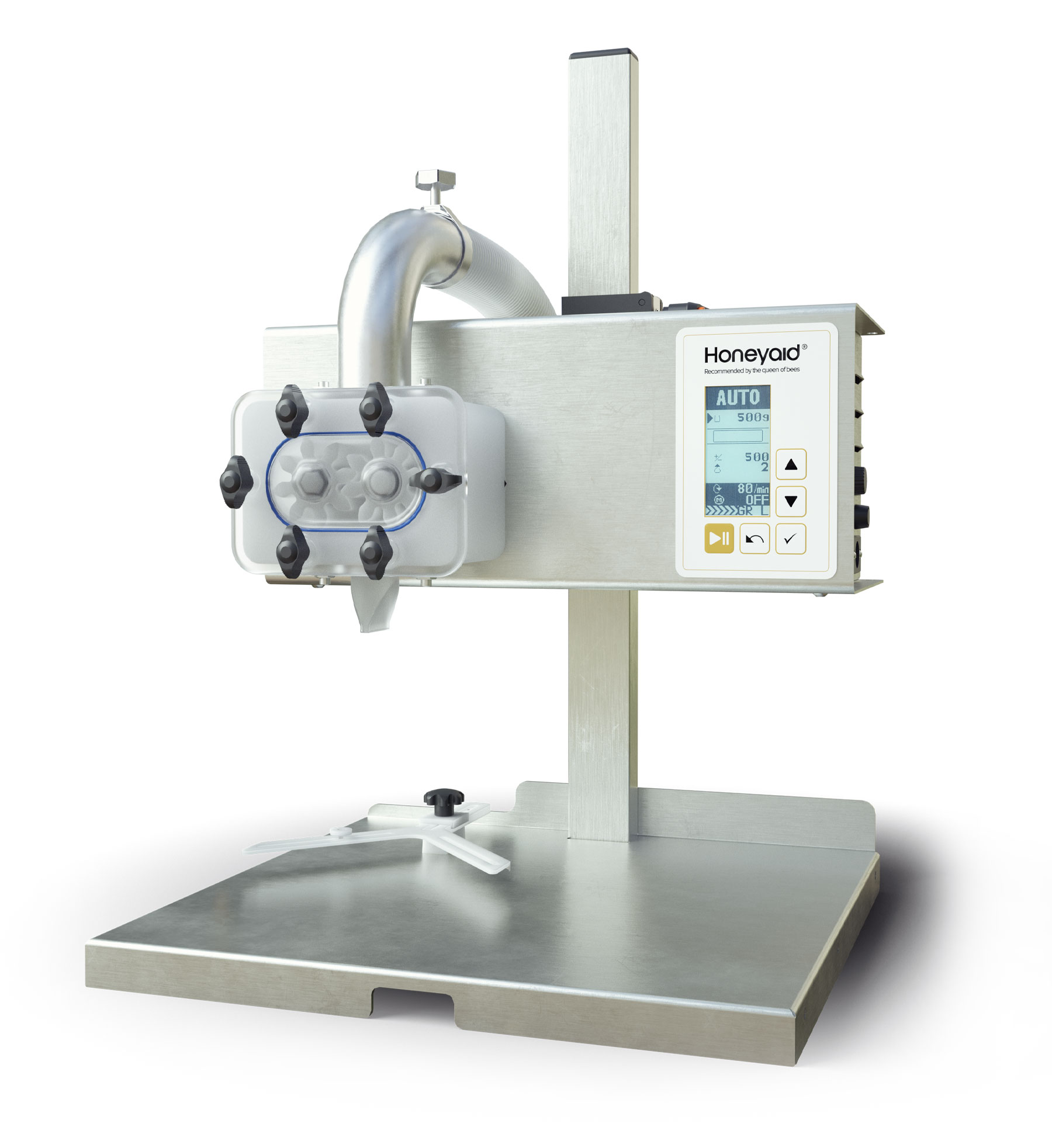

The robust construction of the Honeyaid® honey filling machine guarantees a long service life. Both the machine and the stand are made of high-quality stainless steel. All components comply with the legal requirements.

3. Routine Maintenance

Proper maintenance contributes significantly to extending the service life of the filling machine. It is important to replace wearing parts in good time and to adhere to the recommended maintenance intervals.

4. Modularity

Filling machines with a modular design allow for easy replacement of components and upgrades. This significantly increases the adaptability and service life of the machine.

5. Manufacturer Support

A trustworthy manufacturer is characterised not only by high-quality machines, but also by effective customer service. The support guarantees fast problem solving and offers rapid access to spare parts.

Our service for you

- We guarantee fast and uncomplicated maintenance and repair of your machine.

- You can also order spare and wear parts in our online shop at any time.

All parts of our blog series Quality Standards for filling machines or What do I have to consider when buying a honey filling machine?

- Part 1: General rules and regulations

- Part 2: Construction

- Part 3: Materials

- Part 4: Durability

Share this post:

Related Posts

18.04.2024

HONEYAID®’s ‘Busy as a Bee’ T-Shirt

Our new "Busy as a Bee" collection by HONEYAID® is a must-have for beekeepers and nature enthusiasts seeking something special.

09.04.2024

Looking to fill more than just honey?

From jams to fruit juices to spreads, our FILLOGY® Neo offers a wide range of applications.

09.11.2023

International Conference of the Arab Beekeepers Union

Visit us at the exhibition of the 14th International Conference of the Arab Beekeepers Union

08.11.2023

What do I have to consider when buying a honey filling machine? Part 3: Materials

The materials used in the manufacture of a filling machine have a significant influence on its performance and durability, as well as on ensuring product safety, hygiene and compliance with legal regulations.

08.08.2023

What do I have to consider when buying a honey filling machine? Part 2: Construction

After taking a closer look at the rules and regulations that apply to honey filling machines in the first part of our blog series, we now want to look at the resulting design aspects based on the core piece of a filling machine, the pump head.

20.06.2023

What do I have to consider when buying a honey filling machine? Part 1: General rules and regulations

Part one of our blog series: Applicable standards and directives for machinery in the food sector

24.05.2023

Pumping over for cream stirring with Honeyaid®

With the Honeyaid® bottling machine you fill honey in seconds, but in addition you can also use it to pump and cream honey.

13.04.2023

The Nassenheider® Fill Up 2 becomes Honeyaid®

For over 20 years, beekeepers have valued the original Nassenheider® Fill Up 2 for efficient and reliable dosing of honey. From now on, the semiautomatic honey filling machine …

14.02.2023

From Dresden, all over the world

We have been delivering Honeyaid® filling machines from our small boutique manufacturing company in Dresden to (almost) all countries worldwide.

13.02.2023

Three tips for cleaning

Thanks to its highly compact design, the Honeyaid® is easy and quick to clean. We tell you how to clean your machine optimally so it is in perfect condition for subsequent use.

12.02.2023

Honey bottling at MyHONEY

The MyHONEY project aims to give life to at least 200 new bee colonies every year. To this end, it offers bee sponsorships for companies.

10.02.2023

Women for Bees

Women for Bees is a state-of-the-art female beekeeping entrepreneurship programme launched by UNESCO and Guerlain.

09.02.2023

Bee pollination programs for farmers

The biotech company Beeflow creates and manages pollination programs for farmers which increase crop yields by up to 60%.